Hydrogen Generators by Water Electrolysis of AREVA H2Gen

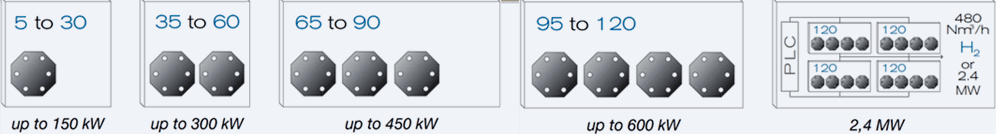

AREVA H2Gen hydrogen generator product line comprises modular architecture that can be implemented as indoor or outdoor versions.

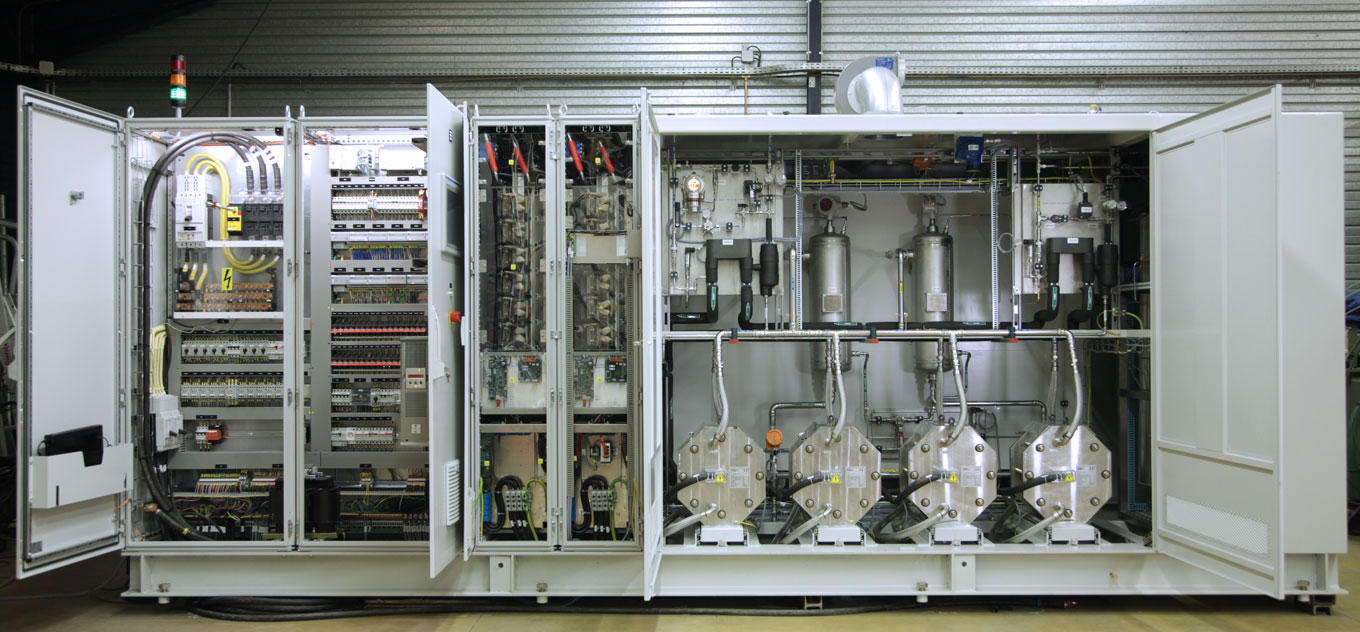

Fully-integrated outdoor unit

Gas Skid

- 2 standardized gas skid versions exist to integrate 1 to 4 stack units of 5 Nm3/h and 30 Nm3/h each.

- Gases are purified by a heat exchanger cooled by a chiller at 4°C to obtain 99.9% H2 purity.

- All our generators are equipped with dry coolers for thermally regulating the process to achieve optimal electro-catalytic reaction efficiency.

- Advanced reverse osmosis and electrodeionization units are included as standard to ensure water quality and to reduce water conductivity 0.2 µS/cm from a tap water source.

Industrial power supply

Each stack has its own individual and highly-efficient 50 kW AC/DC water-cooled rectifier.

Although average power consumption stands at 5 kWh/Nm3 of Hydrogen produced by the system, we provide a power reserve that ensures immediate availability of nominal production of the generator, as well as the ability to produce up to 120% of nominal capacity.

Control system

All our generators are PLC-operated via an HMI (Human Machine Interface) to ensure optimal safety and to monitor processes.

This solution provides various standards of communication protocols and can be connected to the client DCS. The electrolyser can be controlled using client parameters such as volume, flow, pressure, etc.

It can also be remotely monitored by the manufacturer schedule preventive maintenance operations.